Welcome to Looptworks’ Blogs, Videos, & Press, your ultimate resource for all things textile recycling. Discover innovative solutions and sustainable practices in the textile industry as we explore the transformative power of recycling fabrics. From insightful articles and engaging videos to the latest press releases, our content delves into how textile recycling not only reduces waste but also fosters a circular economy. Join us in our mission to create a more sustainable future, one recycled fabric at a time.

Work with Looptwoks and together, we’ll turn textile waste into new opportunities.

Denine has over 20 years of experience driving new business opportunities for leading companies, including E.I. DuPont de Nemours & Company, Inc., The Dow Chemical Company, Outlast Technologies, and DST Systems. She holds a BS from the University of Pittsburgh and a Certification in Executive Management from the Kenan-Flagler School of Business at the University of North Carolina at Chapel Hill.

Tami is a senior accounting leader with over 16 years of experience in the manufacturing and textile industry. Her specialties include process development and implementation, mergers and acquisitions, job and project costing and analysis, and managing complex teams and technical projects. Tami has served as Chief Financial Officer and Controller for a variety of innovative companies, where her analytical skills and strategic mindset helped organizations create efficiencies in their financial systems.

Kelley is a passionate and strategically minded business development leader with more than two decades of experience in the sporting goods apparel industry. He has experience in product construction, league partnerships, retail relationships, supply chain management, sustainability, circularity, and carbon footprint management. Kelley builds successful partnerships by putting the customer first while simultaneously advancing his organization’s business objectives.

Suzy is a product leader and operations expert with more than 25 years of experience in the textile industry. She is passionate about finding creative solutions to complex problems and motivating people to action through vision, strategy, collaboration, and communication. Suzy has proven expertise in product development, sustainability, marketing, supply chains, and innovating processes and best practices to drive results.

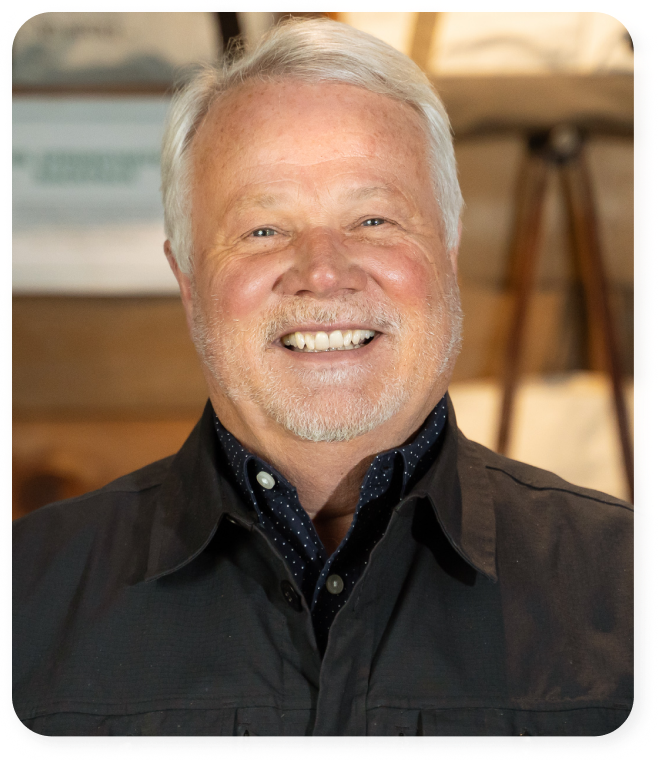

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.