We’re a small and mighty team of apparel industry veterans helping businesses reduce textile waste by transforming excess materials into new fibers.

Looptworks is a Certified B-Corp textile-to-textile recycling specialist offering innovative, scalable solutions for brands and organizations worldwide. Based in Gresham, Oregon, Looptworks is the first and only recycling company in the United States equipped with a circular system capable of processing multiple types of textiles into a range of finished fiber products. The new Looptworks facility is fully operational and features a unique technology that transforms pre-and post-consumer textiles into high-quality recycled fibers. Our process starts where others end.

Vertical Manufacturing: Allows the client to be in control of its production and sourcing.

State-of-the-art Facility: Pre- and post-consumer textiles transformed for next-generation use.

Collaborative Approach: Driving innovation through sustainable innovation through partnership.

Environmentally-Minded: Creating closed-loop systems to conserve water, protect clean air, and build community.

Future-Proofed: Well-positioned to help brands face new government and state recycling laws and regulations.

Looptworks is committed to sustainable practices that promote transparency, traceability and responsible production in the advancement of closed-loop, zero-waste, textile-to-textile recycling. By converting discarded textiles into reusable fibers, Looptworks seeks to lessen the environmental impact of the fashion and textile sectors. B-Corp certified since 2012, Looptworks meets rigorous standards of social and environmental performance, accountability, and transparency. B-Corp Recertification and GRS Certification is expected in 2025. Looptworks’ efforts have resulted in avoiding 5.6M pounds of physical waste and 114K metric tons of carbon emissions and saving 3.4B gallons of water.

Only operational facility in the USA converting textile waste into fiber and high-quality circular products.

Multifaceted textile solutions that avoid landfill and conserve natural resources.

Financial model that provides return on investment.

Made in America output with access to global supply chain suppliers.

Measurable environmental results and full traceability.

The capability to manage large quantities of excess materials.

The 90,000-square-foot manufacturing space is operational for elongated mechanical recycling to produce high-quality recycled fiber for spinning, staple or non-woven end use.

Natural and synthetic textile fibers accepted, including cotton, polyester, cotton/polyester blends, nylon, wool, and acrylics.

Circular model encompassing collection, sortation, sanitizing, deconstruction by fiber type and target end use, fiber separation and color removal to produce a final product of clean feedstock.

Continuous development and process improvement to increase volume and reduce cost.

In 2009, Looptworks launched a mission to recover some of the 17 million pounds of excess textiles from landfills and transform them into new materials. As a team of apparel industry veterans from Nike, Adidas, Jockey, Foot Locker, Royal Robbins, Columbia Sportswear, and Champs Sports, we’d seen the fashion waste problem firsthand.

Today, we’re channeling our 200 years of combined experience into designing closed-loop solutions that protect the air, water, and land we share.

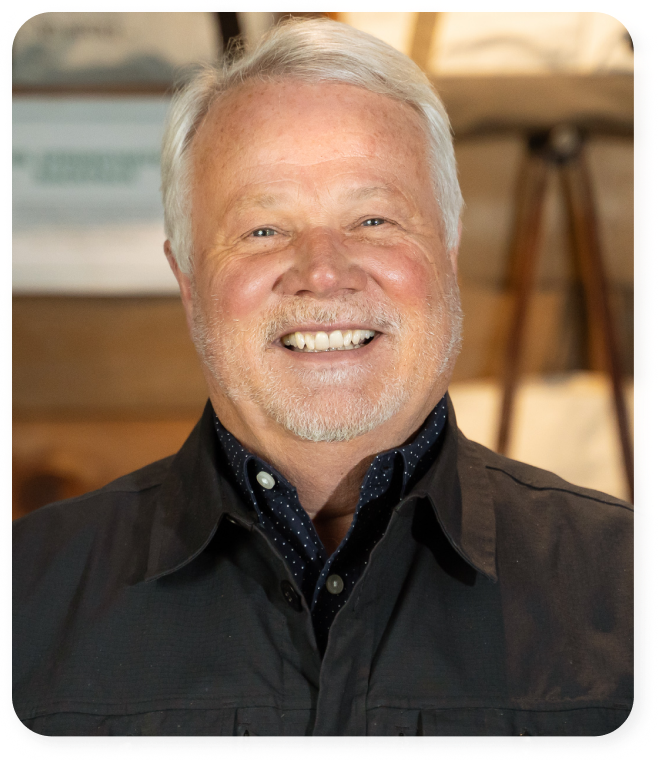

Founder & CEO

Chief Operating Officer

Strategic Partnerships/Sales

Patagonia, SGS, Bluesign

The North Face,

Patagonia, Keen

Nike – Product, Marketing,

Merchandising, Strategy

Pepsico, Savers, Grocery Outlet,

Bargain Hunt

Nike – Global Sales, Marketplace

Development, Strategy

We pioneer new manufacturing methods and create systemic change within the textile industry, rescuing unused textiles and producing quality output materials. We are paving the way for a new kind of future, one where industry fights to protect water, air, and people.

We put the health of our planet at the core of everything we do. We are a zero-waste business and aim to create from only what already exists. We understand that as a for-profit business, it’s our responsibility to actively change the larger system.

We demonstrate our commitment to the planet through transparency and intentionality. We individually and collectively believe in what the future holds and the path we’ve chosen to carve.

B Corporations are certified by the nonprofit B Lab to meet rigorous social and environmental performance standards, accountability, and transparency to solve social and environmental problems. Being recognized by the B Corp community validates our dedication to sustainability and our commitment to minimizing the environmental and social impact on the people who are manufacturing our products.

Want to learn more about who we are and what we do? Reach out today.

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.

Suzy is a product leader and operations expert with more than 25 years of experience in the textile industry. She is passionate about finding creative solutions to complex problems and motivating people to action through vision, strategy, collaboration, and communication. Suzy has proven expertise in product development, sustainability, marketing, supply chains, and innovating processes and best practices to drive results.

Denine has over 20 years of experience driving new business opportunities for leading companies, including E.I. DuPont de Nemours & Company, Inc., The Dow Chemical Company, Outlast Technologies, and DST Systems. She holds a BS from the University of Pittsburgh and a Certification in Executive Management from the Kenan-Flagler School of Business at the University of North Carolina at Chapel Hill.

Tami is a senior accounting leader with over 16 years of experience in the manufacturing and textile industry. Her specialties include process development and implementation, mergers and acquisitions, job and project costing and analysis, and managing complex teams and technical projects. Tami has served as Chief Financial Officer and Controller for a variety of innovative companies, where her analytical skills and strategic mindset helped organizations create efficiencies in their financial systems.

Kelley is a passionate and strategically minded business development leader with more than two decades of experience in the sporting goods apparel industry. He has experience in product construction, league partnerships, retail relationships, supply chain management, sustainability, circularity, and carbon footprint management. Kelley builds successful partnerships by putting the customer first while simultaneously advancing his organization’s business objectives.

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.